rezin halka näme we o-halkalarda haýsy rezin ulanylýar?

rezin halka näme we o-halkalarda haýsy rezin ulanylýar?

Ilki bilen AS568 oring ululygyny barlaň

| AS568 SIZE | Nominal ID | Nominal C / S. | Dýuýmdaky ölçeg belgisi | ± ID | Dýuýmdaky ölçeg CS | ± CS | Ölçeg belgisi mm | ± ID | Ölçegler CS mm | ± C / S. | ||||||||||

| -1 | 1/32 | 1/32 | 0.029 | 0.004 | 0.040 | 0.003 | 0.74 | 0.10 | 1.02 | 0.08 | ||||||||||

| -2 | 3/64 | 3/64 | 0.042 | 0.004 | 0.050 | 0.003 | 1.07 | 0.10 | 1.27 | 0.08 | ||||||||||

| -3 | 1/16 | 1/16 | 0.056 | 0.004 | 0.060 | 0.003 | 1.42 | 0.10 | 1.52 | 0.08 | ||||||||||

| -4 | 5/64 | 1/16 | 0.070 | 0.005 | 0.070 | 0.003 | 1.78 | 0.13 | 1.78 | 0.08 | ||||||||||

| -5 | 3/32 | 1/16 | 0.101 | 0.005 | 0.070 | 0.003 | 2.57 | 0.13 | 1.78 | 0.08 | ||||||||||

| -6 | 1/8 | 1/16 | 0.114 | 0.005 | 0.070 | 0.003 | 2.90 | 0.13 | 1.78 | 0.08 | ||||||||||

| -7 | 5/32 | 1/16 | 0.145 | 0.005 | 0.070 | 0.003 | 3.68 | 0.13 | 1.78 | 0.08 | ||||||||||

| -8 | 3/16 | 1/16 | 0.176 | 0.005 | 0.070 | 0.003 | 4.47 | 0.13 | 1.78 | 0.08 | ||||||||||

| -9 | 7/32 | 1/16 | 0.208 | 0.005 | 0.070 | 0.003 | 5.28 | 0.13 | 1.78 | 0.08 | ||||||||||

| -10 | 1/4 | 1/16 | 0.239 | 0.005 | 0.070 | 0.003 | 6.07 | 0.13 | 1.78 | 0.08 | ||||||||||

| -11 | 5/16 | 1/16 | 0.301 | 0.005 | 0.070 | 0.003 | 7.65 | 0.13 | 1.78 | 0.08 | ||||||||||

| -12 | 3/8 | 1/16 | 0.364 | 0.005 | 0.070 | 0.003 | 9.25 | 0.13 | 1.78 | 0.08 | ||||||||||

| -13 | 7/16 | 1/16 | 0.426 | 0.005 | 0.070 | 0.003 | 10.82 | 0.13 | 1.78 | 0.08 | ||||||||||

| -14 | 1/2 | 1/16 | 0.489 | 0.005 | 0.070 | 0.003 | 12.42 | 0.13 | 1.78 | 0.08 | ||||||||||

| -15 | 9/16 | 1/16 | 0.551 | 0.007 | 0.070 | 0.003 | 14.00 | 0.18 | 1.78 | 0.08 | ||||||||||

| -16 | 5/8 | 1/16 | 0.614 | 0.009 | 0.070 | 0.003 | 15.60 | 0.23 | 1.78 | 0.08 | ||||||||||

| -17 | 11/16 | 1/16 | 0.676 | 0.009 | 0.070 | 0.003 | 17.17 | 0.23 | 1.78 | 0.08 | ||||||||||

| -18 | 3/4 | 1/16 | 0.739 | 0.009 | 0.070 | 0.003 | 18.77 | 0.23 | 1.78 | 0.08 | ||||||||||

| -19 | 13/16 | 1/16 | 0.801 | 0.009 | 0.070 | 0.003 | 20.35 | 0.23 | 1.78 | 0.08 | ||||||||||

| -20 | 7/8 | 1/16 | 0.864 | 0.009 | 0.070 | 0.003 | 21.95 | 0.23 | 1.78 | 0.08 | ||||||||||

| -21 | 15/16 | 1/16 | 0.926 | 0.009 | 0.070 | 0.003 | 23.52 | 0.23 | 1.78 | 0.08 | ||||||||||

| -22 | 1 | 1/16 | 0.989 | 0.010 | 0.070 | 0.003 | 25.12 | 0.25 | 1.78 | 0.08 | ||||||||||

| -23 | 1/16 | 1/16 | 1.051 | 0.010 | 0.070 | 0.003 | 26.70 | 0.25 | 1.78 | 0.08 | ||||||||||

| -24 | 1/8 | 1/16 | 1.114 | 0.010 | 0.070 | 0.003 | 28.30 | 0.25 | 1.78 | 0.08 | ||||||||||

| -25 | 1 3/16 | 1/16 | 1.176 | 0.011 | 0.070 | 0.003 | 29.87 | 0.28 | 1.78 | 0.08 | ||||||||||

| -26 | 1/4 | 1/16 | 1.239 | 0.011 | 0.070 | 0.003 | 31.47 | 0.28 | 1.78 | 0.08 | ||||||||||

| -27 | 1 5/16 | 1/16 | 1.301 | 0.011 | 0.070 | 0.003 | 33.05 | 0.28 | 1.78 | 0.08 | ||||||||||

| -28 | 1 3/8 | 1/16 | 1.364 | 0.013 | 0.070 | 0.003 | 34.65 | 0.33 | 1.78 | 0.08 | ||||||||||

| -29 | 1 1/2 | 1/16 | 1.489 | 0.013 | 0.070 | 0.003 | 37.82 | 0.33 | 1.78 | 0.08 | ||||||||||

| -30 | 1 5/8 | 1/16 | 1.614 | 0.013 | 0.070 | 0.003 | 41.00 | 0.33 | 1.78 | 0.08 | ||||||||||

| -31 | 1 3/4 | 1/16 | 1.739 | 0.015 | 0.070 | 0.003 | 44.17 | 0.38 | 1.78 | 0.08 | ||||||||||

| -32 | 1 7/8 | 1/16 | 1.864 | 0.015 | 0.070 | 0.003 | 47.35 | 0.38 | 1.78 | 0.08 | ||||||||||

| -33 | 2 | 1/16 | 1.989 | 0.018 | 0.070 | 0.003 | 50.52 | 0.46 | 1.78 | 0.08 | ||||||||||

| -34 | 2 1/8 | 1/16 | 2.114 | 0.018 | 0.070 | 0.003 | 53.70 | 0.46 | 1.78 | 0.08 | ||||||||||

| -35 | 2 1/4 | 1/16 | 2.239 | 0.018 | 0.070 | 0.003 | 56.87 | 0.46 | 1.78 | 0.08 | ||||||||||

| -36 | 2 3/8 | 1/16 | 2.364 | 0.018 | 0.070 | 0.003 | 60.05 | 0.46 | 1.78 | 0.08 | ||||||||||

| -37 | 2 1/2 | 1/16 | 2.489 | 0.018 | 0.070 | 0.003 | 63.22 | 0.46 | 1.78 | 0.08 | ||||||||||

| -38 | 2 5/8 | 1/16 | 2.614 | 0.020 | 0.070 | 0.003 | 66.40 | 0.51 | 1.78 | 0.08 | ||||||||||

| -39 | 2 3/4 | 1/16 | 2.739 | 0.020 | 0.070 | 0.003 | 69.57 | 0.51 | 1.78 | 0.08 | ||||||||||

| -40 | 2 7/8 | 1/16 | 2.864 | 0.020 | 0.070 | 0.003 | 72.75 | 0.51 | 1.78 | 0.08 | ||||||||||

| -41 | 3 | 1/16 | 2.989 | 0.024 | 0.070 | 0.003 | 75.92 | 0.61 | 1.78 | 0.08 | ||||||||||

| -42 | 3/4 | 1/16 | 3.239 | 0.024 | 0.070 | 0.003 | 82.27 | 0.61 | 1.78 | 0.08 | ||||||||||

| -43 | 3 1/2 | 1/16 | 3.489 | 0.024 | 0.070 | 0.003 | 88.62 | 0.61 | 1.78 | 0.08 | ||||||||||

| -44 | 3 3/4 | 1/16 | 3.739 | 0.027 | 0.070 | 0.003 | 94.97 | 0.69 | 1.78 | 0.08 | ||||||||||

| -45 | 4 | 1/16 | 3.989 | 0.027 | 0.070 | 0.003 | 101.32 | 0.69 | 1.78 | 0.08 | ||||||||||

| -46 | 4 1/4 | 1/16 | 4.239 | 0.030 | 0.070 | 0.003 | 107.67 | 0.76 | 1.78 | 0.08 | ||||||||||

| -47 | 4 1/2 | 1/16 | 4.489 | 0.030 | 0.070 | 0.003 | 114.02 | 0.76 | 1.78 | 0.08 | ||||||||||

| -48 | 4 3/4 | 1/16 | 4.739 | 0.030 | 0.070 | 0.003 | 120.37 | 0.76 | 1.78 | 0.08 | ||||||||||

| -49 | 5 | 1/16 | 4.989 | 0.037 | 0.070 | 0.003 | 126.72 | 0.94 | 1.78 | 0.08 | ||||||||||

| -50 | 5 1/4 | 1/16 | 5.239 | 0.037 | 0.070 | 0.003 | 133.07 | 0.94 | 1.78 | 0.08 | ||||||||||

| -102 | 1/16 | 3/32 | 0.049 | 0.005 | 0.103 | 0.003 | 1.24 | 0.13 | 2.62 | 0.08 | ||||||||||

| -103 | 3/32 | 3/32 | 0.081 | 0.005 | 0.103 | 0.003 | 2.06 | 0.13 | 2.62 | 0.08 | ||||||||||

| -104 | 1/8 | 3/32 | 0.112 | 0.005 | 0.103 | 0.003 | 2.84 | 0.13 | 2.62 | 0.08 | ||||||||||

| -105 | 5/32 | 3/32 | 0.143 | 0.005 | 0.103 | 0.003 | 3.63 | 0.13 | 2.62 | 0.08 | ||||||||||

| -106 | 3/16 | 3/32 | 0.174 | 0.005 | 0.103 | 0.003 | 4.42 | 0.13 | 2.62 | 0.08 | ||||||||||

| -107 | 7/32 | 3/32 | 0.206 | 0.005 | 0.103 | 0.003 | 5.23 | 0.13 | 2.62 | 0.08 | ||||||||||

| -108 | 1/4 | 3/32 | 0.237 | 0.005 | 0.103 | 0.003 | 6.02 | 0.13 | 2.62 | 0.08 | ||||||||||

| -109 | 5/16 | 3/32 | 0.299 | 0.005 | 0.103 | 0.003 | 7.59 | 0.13 | 2.62 | 0.08 | ||||||||||

| -110 | 3/8 | 3/32 | 0.362 | 0.005 | 0.103 | 0.003 | 9.19 | 0.13 | 2.62 | 0.08 | ||||||||||

| -111 | 7/16 | 3/32 | 0.424 | 0.005 | 0.103 | 0.003 | 10.77 | 0.13 | 2.62 | 0.08 | ||||||||||

| -112 | 1/2 | 3/32 | 0.487 | 0.005 | 0.103 | 0.003 | 12.37 | 0.13 | 2.62 | 0.08 | ||||||||||

| -113 | 9/16 | 3/32 | 0.549 | 0.007 | 0.103 | 0.003 | 13.94 | 0.18 | 2.62 | 0.08 | ||||||||||

| -114 | 5/8 | 3/32 | 0.612 | 0.009 | 0.103 | 0.003 | 15.54 | 0.23 | 2.62 | 0.08 | ||||||||||

| -115 | 11/16 | 3/32 | 0.674 | 0.009 | 0.103 | 0.003 | 17.12 | 0.23 | 2.62 | 0.08 | ||||||||||

| -116 | 3/4 | 3/32 | 0.737 | 0.009 | 0.103 | 0.003 | 18.72 | 0.23 | 2.62 | 0.08 | ||||||||||

| -117 | 13/16 | 3/32 | 0.799 | 0.010 | 0.103 | 0.003 | 20.29 | 0.25 | 2.62 | 0.08 | ||||||||||

| -118 | 7/8 | 3/32 | 0.862 | 0.010 | 0.103 | 0.003 | 21.89 | 0.25 | 2.62 | 0.08 | ||||||||||

| -119 | 15/16 | 3/32 | 0.924 | 0.010 | 0.103 | 0.003 | 23.47 | 0.25 | 2.62 | 0.08 | ||||||||||

| -120 | 1 | 3/32 | 0.987 | 0.010 | 0.103 | 0.003 | 25.07 | 0.25 | 2.62 | 0.08 | ||||||||||

| -121 | 1/16 | 3/32 | 1.049 | 0.010 | 0.103 | 0.003 | 26.64 | 0.25 | 2.62 | 0.08 | ||||||||||

| -122 | 1/8 | 3/32 | 1.112 | 0.010 | 0.103 | 0.003 | 28.24 | 0.25 | 2.62 | 0.08 | ||||||||||

| -123 | 1 3/16 | 3/32 | 1.174 | 0.012 | 0.103 | 0.003 | 29.82 | 0.30 | 2.62 | 0.08 | ||||||||||

| -124 | 1/4 | 3/32 | 1.237 | 0.012 | 0.103 | 0.003 | 31.42 | 0.30 | 2.62 | 0.08 | ||||||||||

| -125 | 1 5/16 | 3/32 | 1.299 | 0.012 | 0.103 | 0.003 | 32.99 | 0.30 | 2.62 | 0.08 | ||||||||||

| -126 | 1 3/8 | 3/32 | 1.362 | 0.012 | 0.103 | 0.003 | 34.59 | 0.30 | 2.62 | 0.08 | ||||||||||

| -127 | 1 7/16 | 3/32 | 1.424 | 0.012 | 0.103 | 0.003 | 36.17 | 0.30 | 2.62 | 0.08 | ||||||||||

| -128 | 1 1/2 | 3/32 | 1.487 | 0.012 | 0.103 | 0.003 | 37.77 | 0.30 | 2.62 | 0.08 | ||||||||||

| -129 | 1 9/16 | 3/32 | 1.549 | 0.015 | 0.103 | 0.003 | 39.34 | 0.38 | 2.62 | 0.08 | ||||||||||

| -130 | 1 5/8 | 3/32 | 1.612 | 0.015 | 0.103 | 0.003 | 40.94 | 0.38 | 2.62 | 0.08 | ||||||||||

| -131 | 1 11/16 | 3/32 | 1.674 | 0.015 | 0.103 | 0.003 | 42.52 | 0.38 | 2.62 | 0.08 | ||||||||||

| -132 | 1 3/4 | 3/32 | 1.737 | 0.015 | 0.103 | 0.003 | 44.12 | 0.38 | 2.62 | 0.08 | ||||||||||

| -133 | 1 13/16 | 3/32 | 1.799 | 0.015 | 0.103 | 0.003 | 45.69 | 0.38 | 2.62 | 0.08 | ||||||||||

| -134 | 1 7/8 | 3/32 | 1.862 | 0.015 | 0.103 | 0.003 | 47.29 | 0.38 | 2.62 | 0.08 | ||||||||||

| -135 | 1 15/16 | 3/32 | 1.925 | 0.017 | 0.103 | 0.003 | 48.90 | 0.43 | 2.62 | 0.08 | ||||||||||

| -136 | 2 | 3/32 | 1.987 | 0.017 | 0.103 | 0.003 | 50.47 | 0.43 | 2.62 | 0.08 | ||||||||||

| -137 | 2 1/16 | 3/32 | 2.050 | 0.017 | 0.103 | 0.003 | 52.07 | 0.43 | 2.62 | 0.08 | ||||||||||

| -138 | 2 1/8 | 3/32 | 2.112 | 0.017 | 0.103 | 0.003 | 53.64 | 0.43 | 2.62 | 0.08 | ||||||||||

| -139 | 2 3/16 | 3/32 | 2.175 | 0.017 | 0.103 | 0.003 | 55.25 | 0.43 | 2.62 | 0.08 | ||||||||||

| -140 | 2 1/4 | 3/32 | 2.237 | 0.017 | 0.103 | 0.003 | 56.82 | 0.43 | 2.62 | 0.08 | ||||||||||

| -141 | 2 5/16 | 3/32 | 2.300 | 0.020 | 0.103 | 0.003 | 58.42 | 0.51 | 2.62 | 0.08 | ||||||||||

| -142 | 2 3/8 | 3/32 | 2.362 | 0.020 | 0.103 | 0.003 | 59.99 | 0.51 | 2.62 | 0.08 | ||||||||||

| -143 | 2 7/16 | 3/32 | 2.425 | 0.020 | 0.103 | 0.003 | 61.60 | 0.51 | 2.62 | 0.08 | ||||||||||

| -144 | 2 1/2 | 3/32 | 2.487 | 0.020 | 0.103 | 0.003 | 63.17 | 0.51 | 2.62 | 0.08 | ||||||||||

| -145 | 2 9/16 | 3/32 | 2.550 | 0.020 | 0.103 | 0.003 | 64.77 | 0.51 | 2.62 | 0.08 | ||||||||||

| -146 | 2 5/8 | 3/32 | 2.612 | 0.020 | 0.103 | 0.003 | 66.34 | 0.51 | 2.62 | 0.08 | ||||||||||

| -147 | 2 11/16 | 3/32 | 2.675 | 0.022 | 0.103 | 0.003 | 67.95 | 0.56 | 2.62 | 0.08 | ||||||||||

| -148 | 2 3/4 | 3/32 | 2.737 | 0.022 | 0.103 | 0.003 | 69.52 | 0.56 | 2.62 | 0.08 | ||||||||||

| -149 | 2 13/16 | 3/32 | 2.800 | 0.022 | 0.103 | 0.003 | 71.12 | 0.56 | 2.62 | 0.08 | ||||||||||

| -150 | 2 7/8 | 3/32 | 2.862 | 0.022 | 0.103 | 0.003 | 72.69 | 0.56 | 2.62 | 0.08 | ||||||||||

| -151 | 3 | 3/32 | 2.987 | 0.024 | 0.103 | 0.003 | 75.87 | 0.61 | 2.62 | 0.08 | ||||||||||

| -152 | 3/4 | 3/32 | 3.237 | 0.024 | 0.103 | 0.003 | 82.22 | 0.61 | 2.62 | 0.08 | ||||||||||

| -153 | 3 1/2 | 3/32 | 3.487 | 0.024 | 0.103 | 0.003 | 88.57 | 0.61 | 2.62 | 0.08 | ||||||||||

| -154 | 3 3/4 | 3/32 | 3.737 | 0.028 | 0.103 | 0.003 | 94.92 | 0.71 | 2.62 | 0.08 | ||||||||||

| -155 | 4 | 3/32 | 3.987 | 0.028 | 0.103 | 0.003 | 101.27 | 0.71 | 2.62 | 0.08 | ||||||||||

| -156 | 4 1/4 | 3/32 | 4.237 | 0.030 | 0.103 | 0.003 | 107.62 | 0.76 | 2.62 | 0.08 | ||||||||||

| -157 | 4 1/2 | 3/32 | 4.487 | 0.030 | 0.103 | 0.003 | 113.97 | 0.76 | 2.62 | 0.08 | ||||||||||

| -158 | 4 3/4 | 3/32 | 4.737 | 0.030 | 0.103 | 0.003 | 120.32 | 0.76 | 2.62 | 0.08 | ||||||||||

| -159 | 5 | 3/32 | 4.987 | 0.035 | 0.103 | 0.003 | 126.67 | 0.89 | 2.62 | 0.08 | ||||||||||

| -160 | 5 1/4 | 3/32 | 5.237 | 0.035 | 0.103 | 0.003 | 133.02 | 0.89 | 2.62 | 0.08 | ||||||||||

| -161 | 5 1/2 | 3/32 | 5.487 | 0.035 | 0.103 | 0.003 | 139.37 | 0.89 | 2.62 | 0.08 | ||||||||||

| -162 | 5 3/4 | 3/32 | 5.737 | 0.035 | 0.103 | 0.003 | 145.72 | 0.89 | 2.62 | 0.08 | ||||||||||

| -163 | 6 | 3/32 | 5.987 | 0.035 | 0.103 | 0.003 | 152.07 | 0.89 | 2.62 | 0.08 | ||||||||||

| -164 | 6 1/4 | 3/32 | 6.237 | 0.040 | 0.103 | 0.003 | 158.42 | 1.02 | 2.62 | 0.08 | ||||||||||

| -165 | 6 1/2 | 3/32 | 6.487 | 0.040 | 0.103 | 0.003 | 164.77 | 1.02 | 2.62 | 0.08 | ||||||||||

| -166 | 6 3/4 | 3/32 | 6.737 | 0.040 | 0.103 | 0.003 | 171.12 | 1.02 | 2.62 | 0.08 | ||||||||||

| -167 | 7 | 3/32 | 6.987 | 0.040 | 0.103 | 0.003 | 177.47 | 1.02 | 2.62 | 0.08 | ||||||||||

| -168 | 7 1/4 | 3/32 | 7.237 | 0.045 | 0.103 | 0.003 | 183.82 | 1.14 | 2.62 | 0.08 | ||||||||||

| -169 | 7 1/2 | 3/32 | 7.487 | 0.045 | 0.103 | 0.003 | 190.17 | 1.14 | 2.62 | 0.08 | ||||||||||

| -170 | 7 3/4 | 3/32 | 7.737 | 0.045 | 0.103 | 0.003 | 196.52 | 1.14 | 2.62 | 0.08 | ||||||||||

| -171 | 8 | 3/32 | 7.987 | 0.045 | 0.103 | 0.003 | 202.87 | 1.14 | 2.62 | 0.08 | ||||||||||

| -172 | 8 1/4 | 3/32 | 8.237 | 0.050 | 0.103 | 0.003 | 209.22 | 1.27 | 2.62 | 0.08 | ||||||||||

| -173 | 8 1/2 | 3/32 | 8.487 | 0.050 | 0.103 | 0.003 | 215.57 | 1.27 | 2.62 | 0.08 | ||||||||||

| -174 | 8 3/4 | 3/32 | 8.737 | 0.050 | 0.103 | 0.003 | 221.92 | 1.27 | 2.62 | 0.08 | ||||||||||

| -175 | 9 | 3/32 | 8.987 | 0.050 | 0.103 | 0.003 | 228.27 | 1.27 | 2.62 | 0.08 | ||||||||||

| -176 | 9 1/4 | 3/32 | 9.237 | 0.055 | 0.103 | 0.003 | 234.62 | 1.40 | 2.62 | 0.08 | ||||||||||

| -177 | 9 1/2 | 3/32 | 9.487 | 0.055 | 0.103 | 0.003 | 240.97 | 1.40 | 2.62 | 0.08 | ||||||||||

| -178 | 9 3/4 | 3/32 | 9.737 | 0.055 | 0.103 | 0.003 | 247.32 | 1.40 | 2.62 | 0.08 | ||||||||||

| -201 | 3/16 | 1/8 | 0.171 | 0.005 | 0.139 | 0.004 | 4.34 | 0.13 | 3.53 | 0.10 | ||||||||||

| -202 | 1/4 | 1/8 | 0.234 | 0.005 | 0.139 | 0.004 | 5.94 | 0.13 | 3.53 | 0.10 | ||||||||||

| -203 | 5/16 | 1/8 | 0.296 | 0.005 | 0.139 | 0.004 | 7.52 | 0.13 | 3.53 | 0.10 | ||||||||||

| -204 | 3/8 | 1/8 | 0.359 | 0.005 | 0.139 | 0.004 | 9.12 | 0.13 | 3.53 | 0.10 | ||||||||||

| -205 | 7/16 | 1/8 | 0.421 | 0.005 | 0.139 | 0.004 | 10.69 | 0.13 | 3.53 | 0.10 | ||||||||||

| -206 | 1/2 | 1/8 | 0.484 | 0.005 | 0.139 | 0.004 | 12.29 | 0.13 | 3.53 | 0.10 | ||||||||||

| -207 | 9/16 | 1/8 | 0.546 | 0.007 | 0.139 | 0.004 | 13.87 | 0.18 | 3.53 | 0.10 | ||||||||||

| -208 | 5/8 | 1/8 | 0.609 | 0.009 | 0.139 | 0.004 | 15.47 | 0.23 | 3.53 | 0.10 | ||||||||||

| -209 | 11/16 | 1/8 | 0.671 | 0.009 | 0.139 | 0.004 | 17.04 | 0.23 | 3.53 | 0.10 | ||||||||||

| -210 | 3/4 | 1/8 | 0.734 | 0.010 | 0.139 | 0.004 | 18.64 | 0.25 | 3.53 | 0.10 | ||||||||||

| -211 | 13/16 | 1/8 | 0.796 | 0.010 | 0.139 | 0.004 | 20.22 | 0.25 | 3.53 | 0.10 | ||||||||||

| -212 | 7/8 | 1/8 | 0.859 | 0.010 | 0.139 | 0.004 | 21.82 | 0.25 | 3.53 | 0.10 | ||||||||||

| -213 | 15/16 | 1/8 | 0.921 | 0.010 | 0.139 | 0.004 | 23.39 | 0.25 | 3.53 | 0.10 | ||||||||||

| -214 | 1 | 1/8 | 0.984 | 0.010 | 0.139 | 0.004 | 24.99 | 0.25 | 3.53 | 0.10 | ||||||||||

| -215 | 1/16 | 1/8 | 1.046 | 0.010 | 0.139 | 0.004 | 26.57 | 0.25 | 3.53 | 0.10 | ||||||||||

| -216 | 1/8 | 1/8 | 1.109 | 0.012 | 0.139 | 0.004 | 28.17 | 0.30 | 3.53 | 0.10 | ||||||||||

| -217 | 1 3/16 | 1/8 | 1.171 | 0.012 | 0.139 | 0.004 | 29.74 | 0.30 | 3.53 | 0.10 | ||||||||||

| -218 | 1/4 | 1/8 | 1.234 | 0.012 | 0.139 | 0.004 | 31.34 | 0.30 | 3.53 | 0.10 | ||||||||||

| -219 | 1 5/16 | 1/8 | 1.296 | 0.012 | 0.139 | 0.004 | 32.92 | 0.30 | 3.53 | 0.10 | ||||||||||

| -220 | 1 3/8 | 1/8 | 1.359 | 0.012 | 0.139 | 0.004 | 34.52 | 0.30 | 3.53 | 0.10 | ||||||||||

| -221 | 1 7/16 | 1/8 | 1.421 | 0.012 | 0.139 | 0.004 | 36.09 | 0.30 | 3.53 | 0.10 | ||||||||||

| -222 | 1 1/2 | 1/8 | 1.484 | 0.015 | 0.139 | 0.004 | 37.69 | 0.38 | 3.53 | 0.10 | ||||||||||

| -223 | 1 5/8 | 1/8 | 1.609 | 0.015 | 0.139 | 0.004 | 40.87 | 0.38 | 3.53 | 0.10 | ||||||||||

| -224 | 1 3/4 | 1/8 | 1.734 | 0.015 | 0.139 | 0.004 | 44.04 | 0.38 | 3.53 | 0.10 | ||||||||||

| -225 | 1 7/8 | 1/8 | 1.859 | 0.018 | 0.139 | 0.004 | 47.22 | 0.46 | 3.53 | 0.10 | ||||||||||

| -226 | 2 | 1/8 | 1.984 | 0.018 | 0.139 | 0.004 | 50.39 | 0.46 | 3.53 | 0.10 | ||||||||||

| -227 | 2 1/8 | 1/8 | 2.109 | 0.018 | 0.139 | 0.004 | 53.57 | 0.46 | 3.53 | 0.10 | ||||||||||

| -228 | 2 1/4 | 1/8 | 2.234 | 0.020 | 0.139 | 0.004 | 56.74 | 0.51 | 3.53 | 0.10 | ||||||||||

| -229 | 2 3/8 | 1/8 | 2.359 | 0.020 | 0.139 | 0.004 | 59.92 | 0.51 | 3.53 | 0.10 | ||||||||||

| -230 | 2 1/2 | 1/8 | 2.484 | 0.020 | 0.139 | 0.004 | 63.09 | 0.51 | 3.53 | 0.10 | ||||||||||

| -231 | 2 5/8 | 1/8 | 2.609 | 0.020 | 0.139 | 0.004 | 66.27 | 0.51 | 3.53 | 0.10 | ||||||||||

| -232 | 2 3/4 | 1/8 | 2.734 | 0.024 | 0.139 | 0.004 | 69.44 | 0.61 | 3.53 | 0.10 | ||||||||||

| -233 | 2 7/8 | 1/8 | 2.859 | 0.024 | 0.139 | 0.004 | 72.62 | 0.61 | 3.53 | 0.10 | ||||||||||

| -234 | 3 | 1/8 | 2.984 | 0.024 | 0.139 | 0.004 | 75.79 | 0.61 | 3.53 | 0.10 | ||||||||||

| -235 | 3 1/8 | 1/8 | 3.109 | 0.024 | 0.139 | 0.004 | 78.97 | 0.61 | 3.53 | 0.10 | ||||||||||

| -236 | 3/4 | 1/8 | 3.234 | 0.024 | 0.139 | 0.004 | 82.14 | 0.61 | 3.53 | 0.10 | ||||||||||

| -237 | 3 3/8 | 1/8 | 3.359 | 0.024 | 0.139 | 0.004 | 85.32 | 0.61 | 3.53 | 0.10 | ||||||||||

| -238 | 3 1/2 | 1/8 | 3.484 | 0.024 | 0.139 | 0.004 | 88.49 | 0.61 | 3.53 | 0.10 | ||||||||||

| -239 | 3 5/8 | 1/8 | 3.609 | 0.028 | 0.139 | 0.004 | 91.67 | 0.71 | 3.53 | 0.10 | ||||||||||

| -240 | 3 3/4 | 1/8 | 3.734 | 0.028 | 0.139 | 0.004 | 94.84 | 0.71 | 3.53 | 0.10 | ||||||||||

| -241 | 3 7/8 | 1/8 | 3.859 | 0.028 | 0.139 | 0.004 | 98.02 | 0.71 | 3.53 | 0.10 | ||||||||||

| -242 | 4 | 1/8 | 3.984 | 0.028 | 0.139 | 0.004 | 101.19 | 0.71 | 3.53 | 0.10 | ||||||||||

| -243 | 4 1/8 | 1/8 | 4.109 | 0.028 | 0.139 | 0.004 | 104.37 | 0.71 | 3.53 | 0.10 | ||||||||||

| -244 | 4 1/4 | 1/8 | 4.234 | 0.030 | 0.139 | 0.004 | 107.54 | 0.76 | 3.53 | 0.10 | ||||||||||

| -245 | 4 3/8 | 1/8 | 4.359 | 0.030 | 0.139 | 0.004 | 110.72 | 0.76 | 3.53 | 0.10 | ||||||||||

| -246 | 4 1/2 | 1/8 | 4.484 | 0.030 | 0.139 | 0.004 | 113.89 | 0.76 | 3.53 | 0.10 | ||||||||||

| -247 | 4 5/8 | 1/8 | 4.609 | 0.030 | 0.139 | 0.004 | 117.07 | 0.76 | 3.53 | 0.10 | ||||||||||

| -248 | 4 3/4 | 1/8 | 4.734 | 0.030 | 0.139 | 0.004 | 120.24 | 0.76 | 3.53 | 0.10 | ||||||||||

| -249 | 4 7/8 | 1/8 | 4.859 | 0.035 | 0.139 | 0.004 | 123.42 | 0.89 | 3.53 | 0.10 | ||||||||||

| -250 | 5 | 1/8 | 4.984 | 0.035 | 0.139 | 0.004 | 126.59 | 0.89 | 3.53 | 0.10 | ||||||||||

| -251 | 5 1/8 | 1/8 | 5.109 | 0.035 | 0.139 | 0.004 | 129.77 | 0.89 | 3.53 | 0.10 | ||||||||||

| -252 | 5 1/4 | 1/8 | 5.234 | 0.035 | 0.139 | 0.004 | 132.94 | 0.89 | 3.53 | 0.10 | ||||||||||

| -253 | 5 3/8 | 1/8 | 5.359 | 0.035 | 0.139 | 0.004 | 136.12 | 0.89 | 3.53 | 0.10 | ||||||||||

| -254 | 5 1/2 | 1/8 | 5.484 | 0.035 | 0.139 | 0.004 | 139.29 | 0.89 | 3.53 | 0.10 | ||||||||||

| -255 | 5 5/8 | 1/8 | 5.609 | 0.035 | 0.139 | 0.004 | 142.47 | 0.89 | 3.53 | 0.10 | ||||||||||

| -256 | 5 3/4 | 1/8 | 5.734 | 0.035 | 0.139 | 0.004 | 145.64 | 0.89 | 3.53 | 0.10 | ||||||||||

| -257 | 5 7/8 | 1/8 | 5.859 | 0.035 | 0.139 | 0.004 | 148.82 | 0.89 | 3.53 | 0.10 | ||||||||||

| -258 | 6 | 1/8 | 5.984 | 0.035 | 0.139 | 0.004 | 151.99 | 0.89 | 3.53 | 0.10 | ||||||||||

| -259 | 6 1/4 | 1/8 | 6.234 | 0.040 | 0.139 | 0.004 | 158.34 | 1.02 | 3.53 | 0.10 | ||||||||||

| -260 | 6 1/2 | 1/8 | 6.484 | 0.040 | 0.139 | 0.004 | 164.69 | 1.02 | 3.53 | 0.10 | ||||||||||

| -261 | 6 3/4 | 1/8 | 6.734 | 0.040 | 0.139 | 0.004 | 171.04 | 1.02 | 3.53 | 0.10 | ||||||||||

| -262 | 7 | 1/8 | 6.984 | 0.040 | 0.139 | 0.004 | 177.39 | 1.02 | 3.53 | 0.10 | ||||||||||

| -263 | 7 1/4 | 1/8 | 7.234 | 0.045 | 0.139 | 0.004 | 183.74 | 1.14 | 3.53 | 0.10 | ||||||||||

| -264 | 7 1/2 | 1/8 | 7.484 | 0.045 | 0.139 | 0.004 | 190.09 | 1.14 | 3.53 | 0.10 | ||||||||||

| -265 | 7 3/4 | 1/8 | 7.734 | 0.045 | 0.139 | 0.004 | 196.44 | 1.14 | 3.53 | 0.10 | ||||||||||

| -266 | 8 | 1/8 | 7.984 | 0.045 | 0.139 | 0.004 | 202.79 | 1.14 | 3.53 | 0.10 | ||||||||||

| -267 | 8 1/4 | 1/8 | 8.234 | 0.050 | 0.139 | 0.004 | 209.14 | 1.27 | 3.53 | 0.10 | ||||||||||

| -268 | 8 1/2 | 1/8 | 8.484 | 0.050 | 0.139 | 0.004 | 215.49 | 1.27 | 3.53 | 0.10 | ||||||||||

| -269 | 8 3/4 | 1/8 | 8.734 | 0.050 | 0.139 | 0.004 | 221.84 | 1.27 | 3.53 | 0.10 | ||||||||||

| -270 | 9 | 1/8 | 8.984 | 0.050 | 0.139 | 0.004 | 228.19 | 1.27 | 3.53 | 0.10 | ||||||||||

| -271 | 9 1/4 | 1/8 | 9.234 | 0.055 | 0.139 | 0.004 | 234.54 | 1.40 | 3.53 | 0.10 | ||||||||||

| -272 | 9 1/2 | 1/8 | 9.484 | 0.055 | 0.139 | 0.004 | 240.89 | 1.40 | 3.53 | 0.10 | ||||||||||

| -273 | 9 3/4 | 1/8 | 9.734 | 0.055 | 0.139 | 0.004 | 247.24 | 1.40 | 3.53 | 0.10 | ||||||||||

| -274 | 10 | 1/8 | 9.984 | 0.055 | 0.139 | 0.004 | 253.59 | 1.40 | 3.53 | 0.10 | ||||||||||

| -275 | 10 1/2 | 1/8 | 10.484 | 0.055 | 0.139 | 0.004 | 266.29 | 1.40 | 3.53 | 0.10 | ||||||||||

| -276 | 11 | 1/8 | 10.984 | 0.065 | 0.139 | 0.004 | 278.99 | 1.65 | 3.53 | 0.10 | ||||||||||

| -277 | 11 1/2 | 1/8 | 11.484 | 0.065 | 0.139 | 0.004 | 291.69 | 1.65 | 3.53 | 0.10 | ||||||||||

| -278 | 12 | 1/8 | 11.984 | 0.065 | 0.139 | 0.004 | 304.39 | 1.65 | 3.53 | 0.10 | ||||||||||

| -279 | 13 | 1/8 | 12.984 | 0.065 | 0.139 | 0.004 | 329.79 | 1.65 | 3.53 | 0.10 | ||||||||||

| -280 | 14 | 1/8 | 13.984 | 0.065 | 0.139 | 0.004 | 355.19 | 1.65 | 3.53 | 0.10 | ||||||||||

| -281 | 15 | 1/8 | 14.984 | 0.065 | 0.139 | 0.004 | 380.59 | 1.65 | 3.53 | 0.10 | ||||||||||

| -282 | 16 | 1/8 | 15.955 | 0.075 | 0.139 | 0.004 | 405.26 | 1.91 | 3.53 | 0.10 | ||||||||||

| -283 | 17 | 1/8 | 16.955 | 0.080 | 0.139 | 0.004 | 430.66 | 2.03 | 3.53 | 0.10 | ||||||||||

| -284 | 18 | 1/8 | 17.955 | 0.085 | 0.139 | 0.004 | 456.06 | 2.16 | 3.53 | 0.10 | ||||||||||

| -309 | 7/16 | 3/16 | 0.412 | 0.005 | 0.210 | 0.005 | 10.46 | 0.13 | 5.33 | 0.13 | ||||||||||

| -310 | 1/2 | 3/16 | 0.475 | 0.005 | 0.210 | 0.005 | 12.07 | 0.13 | 5.33 | 0.13 | ||||||||||

| -311 | 9/16 | 3/16 | 0.537 | 0.007 | 0.210 | 0.005 | 13.64 | 0.18 | 5.33 | 0.13 | ||||||||||

| -312 | 5/8 | 3/16 | 0.600 | 0.009 | 0.210 | 0.005 | 15.24 | 0.23 | 5.33 | 0.13 | ||||||||||

| -313 | 11/16 | 3/16 | 0.662 | 0.009 | 0.210 | 0.005 | 16.81 | 0.23 | 5.33 | 0.13 | ||||||||||

| -314 | 3/4 | 3/16 | 0.725 | 0.010 | 0.210 | 0.005 | 18.42 | 0.25 | 5.33 | 0.13 | ||||||||||

| -315 | 13/16 | 3/16 | 0.787 | 0.010 | 0.210 | 0.005 | 19.99 | 0.25 | 5.33 | 0.13 | ||||||||||

| -316 | 7/8 | 3/16 | 0.850 | 0.010 | 0.210 | 0.005 | 21.59 | 0.25 | 5.33 | 0.13 | ||||||||||

| -317 | 15/16 | 3/16 | 0.912 | 0.010 | 0.210 | 0.005 | 23.16 | 0.25 | 5.33 | 0.13 | ||||||||||

| -318 | 1 | 3/16 | 0.975 | 0.010 | 0.210 | 0.005 | 24.77 | 0.25 | 5.33 | 0.13 | ||||||||||

| -319 | 1/16 | 3/16 | 1.037 | 0.010 | 0.210 | 0.005 | 26.34 | 0.25 | 5.33 | 0.13 | ||||||||||

| -320 | 1/8 | 3/16 | 1.100 | 0.012 | 0.210 | 0.005 | 27.94 | 0.30 | 5.33 | 0.13 | ||||||||||

| -321 | 1 3/16 | 3/16 | 1.162 | 0.012 | 0.210 | 0.005 | 29.51 | 0.30 | 5.33 | 0.13 | ||||||||||

| -322 | 1/4 | 3/16 | 1.225 | 0.012 | 0.210 | 0.005 | 31.12 | 0.30 | 5.33 | 0.13 | ||||||||||

| -323 | 1 5/16 | 3/16 | 1.287 | 0.012 | 0.210 | 0.005 | 32.69 | 0.30 | 5.33 | 0.13 | ||||||||||

| -324 | 1 3/8 | 3/16 | 1.350 | 0.012 | 0.210 | 0.005 | 34.29 | 0.30 | 5.33 | 0.13 | ||||||||||

| -325 | 1 1/2 | 3/16 | 1.475 | 0.015 | 0.210 | 0.005 | 37.47 | 0.38 | 5.33 | 0.13 | ||||||||||

| -326 | 1 5/8 | 3/16 | 1.600 | 0.015 | 0.210 | 0.005 | 40.64 | 0.38 | 5.33 | 0.13 | ||||||||||

| -327 | 1 3/4 | 3/16 | 1.725 | 0.015 | 0.210 | 0.005 | 43.82 | 0.38 | 5.33 | 0.13 | ||||||||||

| -328 | 1 7/8 | 3/16 | 1.850 | 0.015 | 0.210 | 0.005 | 46.99 | 0.38 | 5.33 | 0.13 | ||||||||||

| -329 | 2 | 3/16 | 1.975 | 0.018 | 0.210 | 0.005 | 50.17 | 0.46 | 5.33 | 0.13 | ||||||||||

| -330 | 2 1/8 | 3/16 | 2.100 | 0.018 | 0.210 | 0.005 | 53.34 | 0.46 | 5.33 | 0.13 | ||||||||||

| -331 | 2 1/4 | 3/16 | 2.225 | 0.018 | 0.210 | 0.005 | 56.52 | 0.46 | 5.33 | 0.13 | ||||||||||

| -332 | 2 3/8 | 3/16 | 2.350 | 0.018 | 0.210 | 0.005 | 59.69 | 0.46 | 5.33 | 0.13 | ||||||||||

| -333 | 2 1/2 | 3/16 | 2.475 | 0.020 | 0.210 | 0.005 | 62.87 | 0.51 | 5.33 | 0.13 | ||||||||||

| -334 | 2 5/8 | 3/16 | 2.600 | 0.020 | 0.210 | 0.005 | 66.04 | 0.51 | 5.33 | 0.13 | ||||||||||

| -335 | 2 3/4 | 3/16 | 2.725 | 0.020 | 0.210 | 0.005 | 69.22 | 0.51 | 5.33 | 0.13 | ||||||||||

| -336 | 2 7/8 | 3/16 | 2.850 | 0.020 | 0.210 | 0.005 | 72.39 | 0.51 | 5.33 | 0.13 | ||||||||||

| -337 | 3 | 3/16 | 2.975 | 0.024 | 0.210 | 0.005 | 75.57 | 0.61 | 5.33 | 0.13 | ||||||||||

| -338 | 3 1/8 | 3/16 | 3.100 | 0.024 | 0.210 | 0.005 | 78.74 | 0.61 | 5.33 | 0.13 | ||||||||||

| -339 | 3/4 | 3/16 | 3.225 | 0.024 | 0.210 | 0.005 | 81.92 | 0.61 | 5.33 | 0.13 | ||||||||||

| -340 | 3 3/8 | 3/16 | 3.350 | 0.024 | 0.210 | 0.005 | 85.09 | 0.61 | 5.33 | 0.13 | ||||||||||

| -341 | 3 1/2 | 3/16 | 3.475 | 0.024 | 0.210 | 0.005 | 88.27 | 0.61 | 5.33 | 0.13 | ||||||||||

| -342 | 3 5/8 | 3/16 | 3.600 | 0.028 | 0.210 | 0.005 | 91.44 | 0.71 | 5.33 | 0.13 | ||||||||||

| -343 | 3 3/4 | 3/16 | 3.725 | 0.028 | 0.210 | 0.005 | 94.62 | 0.71 | 5.33 | 0.13 | ||||||||||

| -344 | 3 7/8 | 3/16 | 3.850 | 0.028 | 0.210 | 0.005 | 97.79 | 0.71 | 5.33 | 0.13 | ||||||||||

| -345 | 4 | 3/16 | 3.975 | 0.028 | 0.210 | 0.005 | 100.97 | 0.71 | 5.33 | 0.13 | ||||||||||

| -346 | 4 1/8 | 3/16 | 4.100 | 0.028 | 0.210 | 0.005 | 104.14 | 0.71 | 5.33 | 0.13 | ||||||||||

| -347 | 4 1/4 | 3/16 | 4.225 | 0.030 | 0.210 | 0.005 | 107.32 | 0.76 | 5.33 | 0.13 | ||||||||||

| -348 | 4 3/8 | 3/16 | 4.350 | 0.030 | 0.210 | 0.005 | 110.49 | 0.76 | 5.33 | 0.13 | ||||||||||

| -349 | 4 1/2 | 3/16 | 4.475 | 0.030 | 0.210 | 0.005 | 113.67 | 0.76 | 5.33 | 0.13 | ||||||||||

| -350 | 4 5/8 | 3/16 | 4.600 | 0.030 | 0.210 | 0.005 | 116.84 | 0.76 | 5.33 | 0.13 | ||||||||||

| -351 | 4 3/4 | 3/16 | 4.725 | 0.030 | 0.210 | 0.005 | 120.02 | 0.76 | 5.33 | 0.13 | ||||||||||

| -352 | 4 7/8 | 3/16 | 4.850 | 0.030 | 0.210 | 0.005 | 123.19 | 0.76 | 5.33 | 0.13 | ||||||||||

| -353 | 5 | 3/16 | 4.975 | 0.037 | 0.210 | 0.005 | 126.37 | 0.94 | 5.33 | 0.13 | ||||||||||

| -354 | 5 1/8 | 3/16 | 5.100 | 0.037 | 0.210 | 0.005 | 129.54 | 0.94 | 5.33 | 0.13 | ||||||||||

| -355 | 5 1/4 | 3/16 | 5.225 | 0.037 | 0.210 | 0.005 | 132.72 | 0.94 | 5.33 | 0.13 | ||||||||||

| -356 | 5 3/8 | 3/16 | 5.350 | 0.037 | 0.210 | 0.005 | 135.89 | 0.94 | 5.33 | 0.13 | ||||||||||

| -357 | 5 1/2 | 3/16 | 5.475 | 0.037 | 0.210 | 0.005 | 139.07 | 0.94 | 5.33 | 0.13 | ||||||||||

| -358 | 5 5/8 | 3/16 | 5.600 | 0.037 | 0.210 | 0.005 | 142.24 | 0.94 | 5.33 | 0.13 | ||||||||||

| -359 | 5 3/4 | 3/16 | 5.725 | 0.037 | 0.210 | 0.005 | 145.42 | 0.94 | 5.33 | 0.13 | ||||||||||

| -360 | 5 7/8 | 3/16 | 5.850 | 0.037 | 0.210 | 0.005 | 148.59 | 0.94 | 5.33 | 0.13 | ||||||||||

| -361 | 6 | 3/16 | 5.975 | 0.037 | 0.210 | 0.005 | 151.77 | 0.94 | 5.33 | 0.13 | ||||||||||

| -362 | 6 1/4 | 3/16 | 6.225 | 0.040 | 0.210 | 0.005 | 158.12 | 1.02 | 5.33 | 0.13 | ||||||||||

| -363 | 6 1/2 | 3/16 | 6.475 | 0.040 | 0.210 | 0.005 | 164.47 | 1.02 | 5.33 | 0.13 | ||||||||||

| -364 | 6 3/4 | 3/16 | 6.725 | 0.040 | 0.210 | 0.005 | 170.82 | 1.02 | 5.33 | 0.13 | ||||||||||

| -365 | 7 | 3/16 | 6.975 | 0.040 | 0.210 | 0.005 | 177.17 | 1.02 | 5.33 | 0.13 | ||||||||||

| -366 | 7 1/4 | 3/16 | 7.225 | 0.045 | 0.210 | 0.005 | 183.52 | 1.14 | 5.33 | 0.13 | ||||||||||

| -367 | 7 1/2 | 3/16 | 7.475 | 0.045 | 0.210 | 0.005 | 189.87 | 1.14 | 5.33 | 0.13 | ||||||||||

| -368 | 7 3/4 | 3/16 | 7.725 | 0.045 | 0.210 | 0.005 | 196.22 | 1.14 | 5.33 | 0.13 | ||||||||||

| -369 | 8 | 3/16 | 7.975 | 0.045 | 0.210 | 0.005 | 202.57 | 1.14 | 5.33 | 0.13 | ||||||||||

| -370 | 8 1/4 | 3/16 | 8.225 | 0.050 | 0.210 | 0.005 | 208.92 | 1.27 | 5.33 | 0.13 | ||||||||||

| -371 | 8 1/2 | 3/16 | 8.475 | 0.050 | 0.210 | 0.005 | 215.27 | 1.27 | 5.33 | 0.13 | ||||||||||

| -372 | 8 3/4 | 3/16 | 8.725 | 0.050 | 0.210 | 0.005 | 221.62 | 1.27 | 5.33 | 0.13 | ||||||||||

| -373 | 9 | 3/16 | 8.975 | 0.050 | 0.210 | 0.005 | 227.97 | 1.27 | 5.33 | 0.13 | ||||||||||

| -374 | 9 1/4 | 3/16 | 9.225 | 0.055 | 0.210 | 0.005 | 234.32 | 1.40 | 5.33 | 0.13 | ||||||||||

| -375 | 9 1/2 | 3/16 | 9.475 | 0.055 | 0.210 | 0.005 | 240.67 | 1.40 | 5.33 | 0.13 | ||||||||||

| -376 | 9 3/4 | 3/16 | 9.725 | 0.055 | 0.210 | 0.005 | 247.02 | 1.40 | 5.33 | 0.13 | ||||||||||

| -377 | 10 | 3/16 | 9.975 | 0.055 | 0.210 | 0.005 | 253.37 | 1.40 | 5.33 | 0.13 | ||||||||||

| -378 | 10 1/2 | 3/16 | 10.475 | 0.060 | 0.210 | 0.005 | 266.07 | 1.52 | 5.33 | 0.13 | ||||||||||

| -379 | 11 | 3/16 | 10.975 | 0.060 | 0.210 | 0.005 | 278.77 | 1.52 | 5.33 | 0.13 | ||||||||||

| -380 | 11 1/2 | 3/16 | 11.475 | 0.065 | 0.210 | 0.005 | 291.47 | 1.65 | 5.33 | 0.13 | ||||||||||

| -381 | 12 | 3/16 | 11.975 | 0.065 | 0.210 | 0.005 | 304.17 | 1.65 | 5.33 | 0.13 | ||||||||||

| -382 | 13 | 3/16 | 12.975 | 0.065 | 0.210 | 0.005 | 329.57 | 1.65 | 5.33 | 0.13 | ||||||||||

| -383 | 14 | 3/16 | 13.975 | 0.070 | 0.210 | 0.005 | 354.97 | 1.78 | 5.33 | 0.13 | ||||||||||

| -384 | 15 | 3/16 | 14.975 | 0.070 | 0.210 | 0.005 | 380.37 | 1.78 | 5.33 | 0.13 | ||||||||||

| -385 | 16 | 3/16 | 15.955 | 0.075 | 0.210 | 0.005 | 405.26 | 1.91 | 5.33 | 0.13 | ||||||||||

| -386 | 17 | 3/16 | 16.955 | 0.080 | 0.210 | 0.005 | 430.66 | 2.03 | 5.33 | 0.13 | ||||||||||

| -387 | 18 | 3/16 | 17.955 | 0.085 | 0.210 | 0.005 | 456.06 | 2.16 | 5.33 | 0.13 | ||||||||||

| -388 | 19 | 3/16 | 18.955 | 0.090 | 0.210 | 0.005 | 481.45 | 2.29 | 5.33 | 0.13 | ||||||||||

| -389 | 20 | 3/16 | 19.955 | 0.095 | 0.210 | 0.005 | 506.85 | 2.41 | 5.33 | 0.13 | ||||||||||

| -390 | 21 | 3/16 | 20.955 | 0.095 | 0.210 | 0.005 | 532.25 | 2.41 | 5.33 | 0.13 | ||||||||||

| -391 | 22 | 3/16 | 21.955 | 0.100 | 0.210 | 0.005 | 557.65 | 2.54 | 5.33 | 0.13 | ||||||||||

| -392 | 23 | 3/16 | 22.940 | 0.105 | 0.210 | 0.005 | 582.68 | 2.67 | 5.33 | 0.13 | ||||||||||

| -393 | 24 | 3/16 | 23.940 | 0.110 | 0.210 | 0.005 | 608.08 | 2.79 | 5.33 | 0.13 | ||||||||||

| -394 | 25 | 3/16 | 24.940 | 0.115 | 0.210 | 0.005 | 633.48 | 2.92 | 5.33 | 0.13 | ||||||||||

| -395 | 26 | 3/16 | 25.940 | 0.120 | 0.210 | 0.005 | 658.88 | 3.05 | 5.33 | 0.13 | ||||||||||

| -425 | 4 1/2 | 1/4 | 4.475 | 0.033 | 0.275 | 0.006 | 113.67 | 0.84 | 6.99 | 0.15 | ||||||||||

| -426 | 4 5/8 | 1/4 | 4.600 | 0.033 | 0.275 | 0.006 | 116.84 | 0.84 | 6.99 | 0.15 | ||||||||||

| -427 | 4 3/4 | 1/4 | 4.725 | 0.033 | 0.275 | 0.006 | 120.02 | 0.84 | 6.99 | 0.15 | ||||||||||

| -428 | 4 7/8 | 1/4 | 4.850 | 0.033 | 0.275 | 0.006 | 123.19 | 0.84 | 6.99 | 0.15 | ||||||||||

| -429 | 5 | 1/4 | 4.975 | 0.037 | 0.275 | 0.006 | 126.37 | 0.94 | 6.99 | 0.15 | ||||||||||

| -430 | 5 1/8 | 1/4 | 5.100 | 0.037 | 0.275 | 0.006 | 129.54 | 0.94 | 6.99 | 0.15 | ||||||||||

| -431 | 5 1/4 | 1/4 | 5.225 | 0.037 | 0.275 | 0.006 | 132.72 | 0.94 | 6.99 | 0.15 | ||||||||||

| -432 | 5 3/8 | 1/4 | 5.350 | 0.037 | 0.275 | 0.006 | 135.89 | 0.94 | 6.99 | 0.15 | ||||||||||

| -433 | 5 1/2 | 1/4 | 5.475 | 0.037 | 0.275 | 0.006 | 139.07 | 0.94 | 6.99 | 0.15 | ||||||||||

| -434 | 5 5/8 | 1/4 | 5.600 | 0.037 | 0.275 | 0.006 | 142.24 | 0.94 | 6.99 | 0.15 | ||||||||||

| -435 | 5 3/4 | 1/4 | 5.725 | 0.037 | 0.275 | 0.006 | 145.42 | 0.94 | 6.99 | 0.15 | ||||||||||

| -436 | 5 7/8 | 1/4 | 5.850 | 0.037 | 0.275 | 0.006 | 148.59 | 0.94 | 6.99 | 0.15 | ||||||||||

| -437 | 6 | 1/4 | 5.975 | 0.037 | 0.275 | 0.006 | 151.77 | 0.94 | 6.99 | 0.15 | ||||||||||

| -438 | 6 1/4 | 1/4 | 6.225 | 0.040 | 0.275 | 0.006 | 158.12 | 1.02 | 6.99 | 0.15 | ||||||||||

| -439 | 6 1/2 | 1/4 | 6.475 | 0.040 | 0.275 | 0.006 | 164.47 | 1.02 | 6.99 | 0.15 | ||||||||||

| -440 | 6 3/4 | 1/4 | 6.725 | 0.040 | 0.275 | 0.006 | 170.82 | 1.02 | 6.99 | 0.15 | ||||||||||

| -441 | 7 | 1/4 | 6.975 | 0.040 | 0.275 | 0.006 | 177.17 | 1.02 | 6.99 | 0.15 | ||||||||||

| -442 | 7 1/4 | 1/4 | 7.225 | 0.045 | 0.275 | 0.006 | 183.52 | 1.14 | 6.99 | 0.15 | ||||||||||

| -443 | 7 1/2 | 1/4 | 7.475 | 0.045 | 0.275 | 0.006 | 189.87 | 1.14 | 6.99 | 0.15 | ||||||||||

| -444 | 7 3/4 | 1/4 | 7.725 | 0.045 | 0.275 | 0.006 | 196.22 | 1.14 | 6.99 | 0.15 | ||||||||||

| -445 | 8 | 1/4 | 7.975 | 0.045 | 0.275 | 0.006 | 202.57 | 1.14 | 6.99 | 0.15 | ||||||||||

| -446 | 8 1/2 | 1/4 | 8.475 | 0.055 | 0.275 | 0.006 | 215.27 | 1.40 | 6.99 | 0.15 | ||||||||||

| -447 | 9 | 1/4 | 8.975 | 0.055 | 0.275 | 0.006 | 227.97 | 1.40 | 6.99 | 0.15 | ||||||||||

| -448 | 9 1/2 | 1/4 | 9.475 | 0.055 | 0.275 | 0.006 | 240.67 | 1.40 | 6.99 | 0.15 | ||||||||||

| -449 | 10 | 1/4 | 9.975 | 0.055 | 0.275 | 0.006 | 253.37 | 1.40 | 6.99 | 0.15 | ||||||||||

| -450 | 10 1/2 | 1/4 | 10.475 | 0.060 | 0.275 | 0.006 | 266.07 | 1.52 | 6.99 | 0.15 | ||||||||||

| -451 | 11 | 1/4 | 10.975 | 0.060 | 0.275 | 0.006 | 278.77 | 1.52 | 6.99 | 0.15 | ||||||||||

| -452 | 11 1/2 | 1/4 | 11.475 | 0.060 | 0.275 | 0.006 | 291.47 | 1.52 | 6.99 | 0.15 | ||||||||||

| -453 | 12 | 1/4 | 11.975 | 0.060 | 0.275 | 0.006 | 304.17 | 1.52 | 6.99 | 0.15 | ||||||||||

| -454 | 12 1/2 | 1/4 | 12.475 | 0.060 | 0.275 | 0.006 | 316.87 | 1.52 | 6.99 | 0.15 | ||||||||||

| -455 | 13 | 1/4 | 12.975 | 0.060 | 0.275 | 0.006 | 329.57 | 1.52 | 6.99 | 0.15 | ||||||||||

| -456 | 13 1/2 | 1/4 | 13.475 | 0.070 | 0.275 | 0.006 | 342.27 | 1.78 | 6.99 | 0.15 | ||||||||||

| -457 | 14 | 1/4 | 13.975 | 0.070 | 0.275 | 0.006 | 354.97 | 1.78 | 6.99 | 0.15 | ||||||||||

| -458 | 14 1/2 | 1/4 | 14.475 | 0.070 | 0.275 | 0.006 | 367.67 | 1.78 | 6.99 | 0.15 | ||||||||||

| -459 | 15 | 1/4 | 14.975 | 0.070 | 0.275 | 0.006 | 380.37 | 1.78 | 6.99 | 0.15 | ||||||||||

| -460 | 15 1/2 | 1/4 | 15.475 | 0.070 | 0.275 | 0.006 | 393.07 | 1.78 | 6.99 | 0.15 | ||||||||||

| -461 | 16 | 1/4 | 15.955 | 0.075 | 0.275 | 0.006 | 405.26 | 1.91 | 6.99 | 0.15 | ||||||||||

| -462 | 16 1/2 | 1/4 | 16.455 | 0.075 | 0.275 | 0.006 | 417.96 | 1.91 | 6.99 | 0.15 | ||||||||||

| -463 | 17 | 1/4 | 16.955 | 0.080 | 0.275 | 0.006 | 430.66 | 2.03 | 6.99 | 0.15 | ||||||||||

| -464 | 17 1/2 | 1/4 | 17.455 | 0.085 | 0.275 | 0.006 | 443.36 | 2.16 | 6.99 | 0.15 | ||||||||||

| -465 | 18 | 1/4 | 17.955 | 0.085 | 0.275 | 0.006 | 456.06 | 2.16 | 6.99 | 0.15 | ||||||||||

| -466 | 18 1/2 | 1/4 | 18.455 | 0.085 | 0.275 | 0.006 | 468.76 | 2.16 | 6.99 | 0.15 | ||||||||||

| -467 | 19 | 1/4 | 18.955 | 0.090 | 0.275 | 0.006 | 481.46 | 2.29 | 6.99 | 0.15 | ||||||||||

| -468 | 19 1/2 | 1/4 | 19.455 | 0.090 | 0.275 | 0.006 | 494.16 | 2.29 | 6.99 | 0.15 | ||||||||||

| -469 | 20 | 1/4 | 19.955 | 0.095 | 0.275 | 0.006 | 506.86 | 2.41 | 6.99 | 0.15 | ||||||||||

| -470 | 21 | 1/4 | 20.955 | 0.095 | 0.275 | 0.006 | 532.26 | 2.41 | 6.99 | 0.15 | ||||||||||

| -471 | 22 | 1/4 | 21.955 | 0.100 | 0.275 | 0.006 | 557.66 | 2.54 | 6.99 | 0.15 | ||||||||||

| -472 | 23 | 1/4 | 22.940 | 0.105 | 0.275 | 0.006 | 582.68 | 2.67 | 6.99 | 0.15 | ||||||||||

| -473 | 24 | 1/4 | 23.940 | 0.110 | 0.275 | 0.006 | 608.08 | 2.79 | 6.99 | 0.15 | ||||||||||

| -474 | 25 | 1/4 | 24.940 | 0.115 | 0.275 | 0.006 | 633.48 | 2.92 | 6.99 | 0.15 | ||||||||||

| -475 | 26 | 1/4 | 25.940 | 0.120 | 0.275 | 0.006 | 658.88 | 3.05 | 6.99 | 0.15 | ||||||||||

| AS568 SIZE | Nominal ID | Dýuýmdaky ölçeg belgisi | ± ID | Dýuýmdaky ölçeg CS | ± CS | Ölçeg belgisi mm | ± ID | Ölçegler CS mm | ± C / S. | |||||||||||

| -901 | 3/32 | 0.185 | 0.005 | 0.056 | 0.003 | 4.70 | 0.13 | 1.42 | 0.08 | |||||||||||

| -902 | 1/8 | 0.239 | 0.005 | 0.064 | 0.003 | 6.07 | 0.13 | 1.63 | 0.08 | |||||||||||

| -903 | 3/16 | 0.301 | 0.005 | 0.064 | 0.003 | 7.65 | 0.13 | 1.63 | 0.08 | |||||||||||

| -904 | 1/4 | 0.351 | 0.005 | 0.072 | 0.003 | 8.92 | 0.13 | 1.83 | 0.08 | |||||||||||

| -905 | 5/16 | 0.414 | 0.005 | 0.072 | 0.003 | 10.52 | 0.13 | 1.83 | 0.08 | |||||||||||

| -906 | 3/8 | 0.468 | 0.005 | 0.078 | 0.003 | 11.89 | 0.13 | 1.98 | 0.08 | |||||||||||

| -907 | 7/16 | 0.530 | 0.007 | 0.082 | 0.003 | 13.46 | 0.18 | 2.08 | 0.08 | |||||||||||

| -908 | 1/2 | 0.644 | 0.009 | 0.087 | 0.003 | 16.36 | 0.23 | 2.21 | 0.08 | |||||||||||

| -909 | 9/16 | 0.706 | 0.009 | 0.097 | 0.003 | 17.93 | 0.23 | 2.46 | 0.08 | |||||||||||

| -910 | 5/8 | 0.755 | 0.009 | 0.097 | 0.003 | 19.18 | 0.23 | 2.46 | 0.08 | |||||||||||

| -911 | 11/16 | 0.863 | 0.009 | 0.116 | 0.004 | 21.92 | 0.23 | 2.95 | 0.10 | |||||||||||

| -912 | 3/4 | 0.924 | 0.009 | 0.116 | 0.004 | 23.47 | 0.23 | 2.95 | 0.10 | |||||||||||

| -913 | 13/16 | 0.986 | 0.010 | 0.116 | 0.004 | 25.04 | 0.25 | 2.95 | 0.10 | |||||||||||

| -914 | 7/8 | 1.047 | 0.010 | 0.116 | 0.004 | 26.59 | 0.25 | 2.95 | 0.10 | |||||||||||

| -916 | 1 | 1.171 | 0.010 | 0.116 | 0.004 | 29.74 | 0.25 | 2.95 | 0.10 | |||||||||||

| -918 | 1/8 | 1.355 | 0.012 | 0.116 | 0.004 | 34.42 | 0.30 | 2.95 | 0.10 | |||||||||||

| -920 | 1/4 | 1.475 | 0.014 | 0.118 | 0.004 | 37.47 | 0.36 | 3.00 | 0.10 | |||||||||||

| -924 | 1 1/2 | 1.720 | 0.014 | 0.118 | 0.004 | 43.69 | 0.36 | 3.00 | 0.10 | |||||||||||

| -928 | 1 3/4 | 2.090 | 0.018 | 0.118 | 0.004 | 53.09 | 0.46 | 3.00 | 0.10 | |||||||||||

| -932 | 2 | 2.337 | 0.018 | 0.118 | 0.004 | 59.36 | 0.46 | 3.00 | 0.10 | |||||||||||

Ikinji - gysyş tizligi we uzalýan mukdarorings

O halkasy adaty ekstrudirlenen möhürdir.O halkasynyň kesiş diametriniň gysyş gatnaşygy we uzalýan mukdary möhürleýiş dizaýnynyň esasy mazmuny bolup, möhürleme öndürijiligi we hyzmat möhleti üçin möhüm ähmiýete eýe.O-halkanyň gowy möhürleme täsiri, esasan, O-halkanyň ululygynyň we çukuryň ululygynyň dogry gabat gelmegine baglydyr, möhürleýji halkanyň göwnejaý gysylmagyny we uzalýan mukdaryny emele getirýär.

1. Gysyş tizligi

W gysyş tizligi adatça aşakdaky ýaly aňladylýar:

W = (d0 h) / d0× 100%

Formulada, d0- erkin ýagdaýda (mm) O halkasynyň kesişýän diametri;

H - O halka çukurynyň aşagy bilen möhürlenen üstüň arasyndaky aralyk (çukur çuňlugy), ýagny gysylandan soň O halkasynyň kesiş beýikligi (mm)

2.O-halkanyň gysyş gatnaşygy saýlanylanda aşakdaky üç tarapy göz öňünde tutmaly:

(1).Möhüm aragatnaşyk üçin ýeterlik ýer bolmaly;(2).Sürtülme güýjüni azaltmaga synanyşyň;(3).Hemişelik deformasiýadan gaça durmaga synanyşyň.

Aboveokardaky faktorlardan olaryň arasynda gapma-garşylyklaryň bardygyny görmek kyn däl.Comokary gysyş tizligi ýokary kontakt basyşyny alyp biler, ýöne aşa gysyş tizligi süýşýän sürtülmäni we hemişelik deformasiýany ýokarlandyrýar.Gysyş tizligi gaty az bolsa, bu gysyş mukdarynyň ýitip gitmegine we syzmagyna sebäp bolýan möhürleýji çukuryň O-ring ýalňyşlygy sebäpli bolup biler.Şonuň üçin “O-halkanyň” gysyş gatnaşygyny saýlanyňyzda dürli faktorlary ölçemeli.Adatça, statiki möhürleriň gysyş tizligi dinamiki möhürlerden has uly, ýöne iň ýokary bahasy 25% -den az bolmalydyr.Otherwiseogsam, gysyş stresleri ep-esli gowşar we aşa ýokary hemişelik iş şertlerinde aşa hemişelik deformasiýa ýüze çykar.O halkaly möhürler üçin W gysyş nisbesini saýlamak, statiki ýa-da dinamiki möhürler ýaly ulanyş şertlerini göz öňünde tutmalydyr;Statik möhürlemäni radial möhürlemek we eksenel möhürlemek diýip bölmek mümkin;Radial möhürleriň syzmak boşlugy (ýa-da silindr görnüşli statiki möhürler) radial boşluk, eksenel möhürleriň (ýa-da planik statiki möhürleriň) syzyş boşlugy eksenel boşlukdyr.Okuň möhürlenmegi, basyş gurşawynyň O diametriniň içki diametri ýa-da daşky diametri boýunça hereket edýändigine baglylykda iki ýagdaýa bölünýär: içerki basyş we daşarky basyş.Içerki basyşyň ýokarlanmagy uzalmagyna getirýär, daşarky basyş bolsa O halkasynyň başlangyç uzalmagyny peseldýär.Aboveokarda agzalan statiki möhürleriň dürli görnüşlerinde, O halkasyndaky möhürleýjiniň hereketiniň dürli ugurlary bar, şonuň üçin basyşdan öňki dizaýn hem başga.Dinamiki möhürler üçin ikitaraplaýyn hereket möhürleri bilen aýlanýan hereket möhürlerini tapawutlandyrmaly.

(2).Statik möhürlemek: Iki taraplaýyn möhürleýji enjamlar ýaly silindr görnüşli statiki möhürleýiş enjamlary, adatça W = 10% -den 15% -e çenli alýar;Tekiz statiki möhürleýji enjam W = 15% ~ 30% alýar.Dinamiki möhürlemek üçin ony üç ýagdaýa bölmek mümkin;Iki taraplaýyn hereket, adatça W = 10% -den 15% -e çenli kabul edilýär.Aýlanýan hereket möhürleri üçin gysyş gatnaşygy saýlanylanda, Joule ýylylyk täsiri göz öňünde tutulmalydyr.Umuman aýdanyňda, aýlanmak üçin ulanylýan O halkasynyň içki diametri miliň diametrinden 3% -5%, daşky diametriň gysyş gatnaşygy W = 3% -8%.Pes sürtülme sporty üçin, O-halkalar, sürtülme garşylygy azaltmak üçin, W = 5% -8% has kiçi gysyş gatnaşygy bilen saýlanýar.Mundan başga-da, orta we temperatura sebäpli dörän kauçuk materiallaryň giňelmegi hem göz öňünde tutulmalydyr.Adatça, berlen gysyş deformasiýasynyň daşynda iň ýokary rugsat berilýän giňeliş tizligi 15% -dir.Bu aralykdan geçmek, material saýlamagyň ýerlikli däldigini, ýerine başga materiallaryň O halkalaryny ulanmalydygyny ýa-da berlen gysyş deformasiýasynyň düzedilmelidigini görkezýär.

(3)Uzalýan mukdar,Möhürleýji çukura oturdylansoň, O halkasy, adatça, belli bir derejede uzalýar.Gysyş tizligi ýaly, uzalmagyň mukdary hem O-halkanyň möhürlenmegine we hyzmat ediş möhletine ep-esli täsir edýär.Köp mukdarda uzalmak diňe bir O-halkany gurnamagy kynlaşdyrman, eýsem d0 kesişýän diametriniň üýtgemegi sebäpli gysylma derejesini hem peseldýär we syzmagyna sebäp bolýar.Uzalýan mukdar aşakdaky ýaly aňladylyp bilner:α= (d + d0) / (d1 + d0)Formulada d - miliň diametri (mm);D1-- O halkanyň içki diametri (mm).Uzalýan mukdar 1% -5%.O-halkanyň uzalýan mukdary üçin maslahat berilýän bahalar tablisada berilýär.O halkasynyň uzalýan mukdary, tablisanyň saýlama çägine görä miliň diametriniň ululygyna görä saýlanyp bilner.O-halka üçin gysyş gatnaşygy we uzaldyş mukdary

Üçünjiden, içki diametri (ID), daşky diametri (OD) we O halkasynyň sim diametri (C / S) arasyndaky baglanyşyk.

OD = ID + C / S * 2 Mysal üçin: ID = 3MM C / S = 1MM OD = 3MM + 1 * 2 = 5MM

O-halkalary öndürmekde köplenç ulanylýan dördünji materiallar

- NBR:NBR O-RING

ajaýyp ýag garşylygy, benzol garşylygy, ýylylyga garşylygy we fiziki we mehaniki aýratynlyklary bar we nebite çydamly rezin önümleri üçin umumy çig mallardan biridir.Nebite çydamly gazetler, gazetler, rezin şlanglar, uçar poçta gutulary, çeýe gaplamak, rezin rulonlary, kabel materiallaryny we ýelimleri çap etmekde we boýamakda giňden ulanylýar.

- EPDM:EPDM O-RING

ajaýyp mehaniki aýratynlyklary, himiki garşylygy we ýylylyga garşylygy bilen bir hatarda güýçli howa garşylygyny görkezýär.Etilen propilen dien monomer (EPDM) ozona garşylygy, ýylylyga garşylygy, howa garşylygy we pes ýumşaklygy boýunça ajaýyp häsiýetleri görkezýär, bu bolsa ozona çydamly, howa çydamly we UV çydamly programmalar üçin amatly bolýar.Şeýle-de bolsa, öz gurluş aýratynlyklary sebäpli ýangynyň yza galmagy, ýagyň garşylygy we EPDM rezininiň ýelmeşmegi birneme pes.Şeýle-de bolsa, reziniň bu görnüşi esasy zynjyr bilen doýgun gurluşa eýedir we biri-biriniň güýçli we gowşak taraplaryny öwrenip, öndürijiligi gowulandyrmak üçin beýleki materiallar bilen garylyp bilner.

- VMQ (SILICONE):SILIKON O-RING

Temperatura we ýag garşylygy bilen.Silikon kauçuk pes temperatura garşylygy bar we adatça -55-de işläp biler℃.Fenil girizilenden soň -73-e ýetip biler℃.Silikon kauçukyň ýylylyga garşylygy hem ajaýyp we uzak wagtlap 180-de işläp biler℃.Birnäçe hepdeden ýa-da ondanam köp elastiklige 200-den ýokary bolsa-da çydap bilýär℃we 300-den ýokary ýokary temperatura derrew çydap bilýär℃.Silikon kauçuk gowy dem alýar we sintetik polimerleriň arasynda kislorod geçirijiligi iň ýokarydyr.Mundan başga-da, silikon kauçuk fiziologiki inertligiň görnükli aýratynlyklaryna eýedir we koagulýasiýa sebäp bolmaýar we lukmançylyk pudagynda giňden ulanylýar.

- VITON (FKM FPM):VITON O-RING

ajaýyp ýylylyga garşylygy, okislenme garşylygy, ýag garşylygy, poslama garşylygy we atmosfera garramagyna garşylygy bar we howa, awiasiýa, awtoulag, nebit we durmuş enjamlary ýaly ugurlarda giňden ulanylýar.Milli goranyşyň öňdebaryjy pudaklarynda çalşyp bolmajak esasy material

- HNBR:HNBR O-RING

ýagyň gowy garşylygy bar (ýangyç ýagyna, çalgy ýagyna we ysly erginlere gowy garşylyk);Örän doýgun gurluşy sebäpli, gowy ýylylyga garşylygy, ajaýyp himiki poslama garşylygy (Freona, kislota we aşgazana gowy garşylyk), ozonyň ajaýyp garşylygy we ýokary gysylma hemişelik deformasiýa garşylygy bar;Şol bir wagtyň özünde, wodorodlaşdyrylan nitril kauçuk hem ýokary güýç, ýokary ýyrtyk garşylyk we ajaýyp könelişme ýaly häsiýetlere eýe bolup, ony hemmetaraplaýyn öndürijilik taýdan iň oňat rezinleriň birine öwürýär.

- CR (neopren):CR O-RING

gowy fiziki we mehaniki aýratynlyklary, ýag garşylygy, ýylylyga garşylygy, ýangyna garşylygy, gün şöhlesine garşylygy, ozona garşylygy, kislota we aşgar garşylygy we himiki reagent garşylygy bilen..Etmezçiligi, sowuk garşylygy we saklanyş durnuklylygy.Highokary dartyş güýji, uzalmagy, tersine kristallylygy we gowy ýelmeşmesi bar.Garramaga we ýylylyga çydamly.Ajaýyp nebit we himiki garşylyk

FVMQ: Gowy fiziki we mehaniki aýratynlyklary we himiki durnuklylygy bolan FVMQ O-RING, 200-de uzak möhletli ulanmaga ukyply℃we 250-de gysga möhletli ulanmak℃;Çekiş nokady -20 aralygynda℃-40℃;Ajaýyp orta garşylyk, organiki erginlere, organiki däl kislotalara we oksidantlara garşy ajaýyp durnuklylyk, esasanam ajaýyp kislota garşylygy;Ajaýyp howa garşylygy we ozona garşylygy bar.Birnäçe ýyllap atmosfera sezewar bolandan soň, fiziki we mehaniki aýratynlyklary gaty az üýtgeýär we mikroorganizmlere täsiri hem birneme durnukly

- FEPM (Aflas):FEPM O-RING

oňat durnuklylygy, himiki garşylygy, esasanam ýokary mukdarda kislotalara, aşgarlara we dürli görnüşli ulag ýangyjy, çalgy ýaglary, tormoz ýaglary, mineral ýaglar we silikon ýaglary üçin güýçli oksidleýji serişdelere, şeýle hem ýokary basyşly suwa ajaýyp garşylygy bar. bug, suw we elektrik izolýasiýasy.Dem alyş ukyby pes we -400-den 200 gradusa çenli temperaturada ulanylyp bilner

- FFKM:FFKM O-RING

Polietetrafluoroetileniň çeýeligi we ýylylyk we himiki durnuklylygy bar.Uzak möhletli iş temperaturasy -39 ~ 288 gradus, gysga möhletli 315 gradusa çenli, henizem belli bir derejede plastisit derejesine eýe, gaty, ýöne döwük däl we egilip bilner.Ftorly erginleriň çişmeginden başga ähli himiki maddalar üçin durnukly.häzirki wagtda dünýädäki iň gymmat rezin. Marka:Kalrez

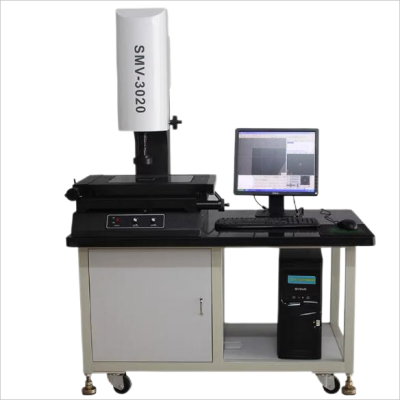

Bäşinji rezin O-halka aýratynlyklary Ölçeme usullary we gurallary.

Umumy ölçeg gurallary bar:

1-Precokary takyklyk proýektory

Gurallaryň aýratynlyklary:Aragatnaşyk däl ölçeg, ölçegi görünmeýän we inçe diwarly we ýumşak bölekleri ölçemek üçin amatly edýär; Güýçli şekil ulaltmak funksiýasyna we has kiçi ölçeg ölçeg ukybyna eýe; Çalt ölçeg tizligi ölçeg netijeliligini ep-esli ýokarlandyrýar; Nusga nokatlarynyň ýokary dykyzlygy ölçegiň ýokary ygtybarlylygyny üpjün edýär; Amatly gysyş.

2-Elektron sanly hasaplaýjy

Gurallaryň aýratynlyklary:Ölçeg bahalaryny sanly görkezmek üçin kuwwatly we magnit gözenekleri ýaly ölçeg ulgamlaryny ulanýan uzynlyk ölçeg guraly.Köplenç ulanylýan çözgüt 0.01mm, rugsat berlen ýalňyşlyk ± 0.03mm / 150mm.Şeýle hem 0.005mm durulykda, rugsat berlen ýalňyşlyk ± 0.015mm / 150mm bolan ýokary takyklykly sanly hasaplaýjylar bar.Şeýle hem 0.001mm durulykda (Anyi ölçeg gurallarynyň milli patenti we diňe olar öndürip biler) köpugurly sanly displeý mikrometr kaliperi bar, rugsat berlen ýalňyşlyk ± 0.005mm / 50mm.Düşünjeli we düşnükli okamak sebäpli ölçeg netijeliligi ýokarydyr.

3-π hökümdar(PITAPE)

Gurallaryň aýratynlyklary:

1. π hökümdar elastik polat zolakdan durýar.Onuň iki ujy degişlilikde esasy we kömekçi hökümdarlar bilen nagyşlanýar.Esasy hökümdaryň iň pes gutardyş bahasy 0,5 mm ýa-da 1mm;Kömekçi hökümdaryň iň pes gutardyş bahalary 0.02mm, 0.05mm, 0.01mm, 0.1mm we ş.m.

2. Ulanylanda π hökümdary iş bölegine daňyň we ölçenen eseriň ortaça diametrini gönüden-göni okamak üçin birkemsiz okamak usulyny ulanyň.

- Üstünlikleri we kemçilikleri

(1).Highokary takyklyk: Diametri hökümdaryň daş-töweregi bilen ölçelýändigi sebäpli, hökümdaryň önümçiliginde bellik ýalňyşlygy π esse azaldylyp, ölçeg netijelerinde şöhlelendirilip bilner.Şeýlelik bilen 500 500 mm-den ýokary diametrli ölçeglerde, onuň takyklygy ýerli kaliperden has ýokary.galmak φ Bu artykmaçlyk, 1000 mm-den ýokary ölçeglerde aýratyn bellidir.

(2).Polat bölekleri π hökümdar bilen ölçelende, iş böleginiň temperaturasyna täsir etmeýär.Munuň sebäbi π hökümdaryň gaty inçe bolmagy we ölçeg wagtynda gaty gysga wagtyň içinde synag edilen bölek bilen beýleki ýylylyk bolar.Mundan başga-da, ýylylyk giňelme koeffisiýentleri gaty ýakyn, esasan temperaturanyň täsirini ýeňip geçýär.

(3. Uly we goşmaça uly diametrleri ölçemekde kömekçi komponentleri (patentlenen magnit köprüleri) ulanmak bir gezekde bir adamyň aňsat işlemegine mümkinçilik berýär.

(4).Inçe diwarly bölekleri ölçemek, eseriň deformasiýasyna sebäp bolmak aňsat däl.(5).Daşamak we saklamak üçin amatly (6).Bahasy pes.

(7).Adetmezçiligi: Okamagy gulplap bolmaýar;Alumurtgalyk ýaly geometrik gyşarmalary ölçäp bolmaýar.

Altynjy “O-ring” ulanyň we “o-ring” gurnama.

1. O halkasyny ulanmak

O-halka dürli gidrawliki we pnewmatiki komponentleriň, silindr ýüzleriniň we flanes ýüzleriniň bogunlarynda giňden ulanylýar.Hereket wagtynda ulanylýan O halkalar üçin, iş basyşy 9,8Mpa-dan ýokary bolup, bir taraplaýyn basyşa sezewar bolanda, O halkasynyň beýleki tarapynda basyş ugrunda saklaýjy halka oturdylmalydyr;Iki taraplaýyn gysylsa, O halkasynyň iki gapdalynda saklaýjy halkany goýuň.Sürtülmäni azaltmak üçin takdyr şekilli saklaýjy halkalar hem ulanylyp bilner.Çep tarapdan basyş suwuklygy ulanylanda, sag saklaýjy halka ýokaryk çykarylýar we çep saklaýjy halka möhürlenen ýüz bilen degmeýär, şeýlelik bilen sürtülme güýji azalýar.Umuman aýdanyňda, saklaýan halkalary ulanmak möhürleýji enjamyň sürtülme güýjüni ýokarlandyrýar we takdyr şekilli saklaýjy halkalar bu sürtülme güýjüni azaltmakda möhüm ähmiýete eýe.Kesgitli O-halkalar üçin, iş basyşy 32Mpa-dan ýokary bolanda saklaýjy halka hem talap edilýär.

2. Oring gurnama

O-halkalary gurnamagyň hili, möhürleme işine we hyzmat möhletine ep-esli täsir edýär.Syzmak meselesi köplenç erbet gurnama sebäpli ýüze çykýar. Gurmak prosesi wagtynda O halkasynyň çyzylmagyna, ýalňyş ýazylmagyna ýa-da burulmagyna ýol berilmeýär.Gurnamagyň öňüsyrasynda möhürleýji çukur we möhürleýji jübüt gaty arassalanmalydyr;Şol bir wagtyň özünde, Oringiň gurnalan döwründe geçmeli ýerlere çalgy ýagyny çalyň. O-halkanyň gurnama wagtynda ýiti burçlar we sapaklar ýaly ýiti gyralary bilen kesilmeginiň ýa-da çyzylmagynyň öňüni almak üçin, 15 º 30 º gurşun burçy, gurnamanyň şahasynyň ujunda we deşik ujunda galdyrylmalydyr.O halkasy daşarky sapakdan geçmeli bolanda daşarky ýüpi ýapmak üçin ýörite inçe diwarly metal gollanma ýeňi ulanylmaly;O-halkasy orifisden geçmeli bolsa, O-halkadaky çyzyklaryň öňüni almak üçin, degişli diagonaly görnüşe öwrülmeli.Çukuryň eňňit burçy adatça a = 120 º ~ 140 º

Bu ýerden köp bilim alyp bilersiňiz.Soňrak bolsa, käbir bilimleri hödürlärisýag möhürleri, gidrawlik möhür,ýa-da başgaýöriteleşdirilen kauçuk bölekleriýalyPişigiň ýag möhüri, NBR ýag möhüri, FKM nebit möhüri,TC ýag möhüri, Inçekesel möhüri TA ýag möhüri, SC ýag möhüri SB ýag möhüri,porşen möhüri, hasa möhüri ,bahar möhüri ,berkidilen möhür, käse möhüri, tozan möhüri,Süpürgiç möhüri, ýüzük geýmek, ätiýaçlyk halka,rezin simler, halka simleri, şonuň üçin bu bilimleri hemmelere tanatmak üçin has köp wagt gerek.Wagtyňyz üçin sag boluň!